Plastic Recycling | Production process drawing

How do you explain the process of turning waste into raw materials clearly?

/f/81631/800x800/5a0651fab2/marco-visuele-verbinders-rotterdam-zakelijk-tekenen-verbeelding-proces-idee-product-dienst-in-tekening.jpg)

Marco

/f/81631/800x800/c2b541d01f/jeroen-vierkant-visuele-verbinders-animaties-praatplaat-sneltekenen-zakelijk-tekenen-den-haag-caballerofabriek.jpg)

Jeroen

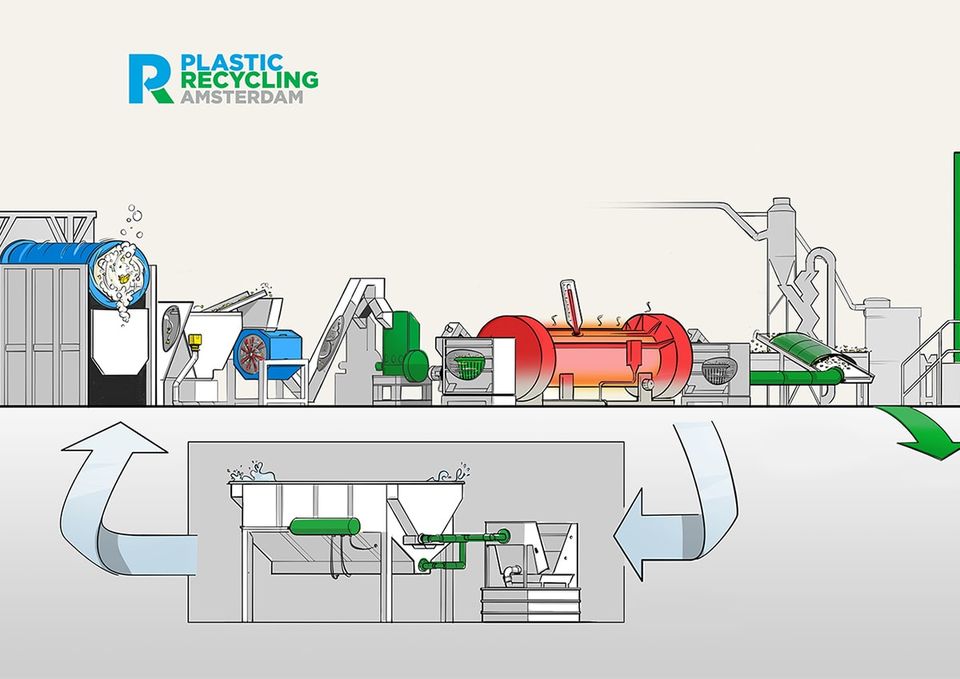

Plastic Recycling Amsterdam offers an innovative solution for recycling plastic waste that is better than current alternatives in the plastic chain. Inside the factory, there is a sequence of machines. To encourage customers to use their service or to attract investors to buy your concept, it is important to be able to explain clearly what they do. They have simplified this complex process and created drawings to illustrate the step-by-step process so that you can easily explain what happens during production. (To protect sensitive information, we have not included any text in the illustrations on this website.)

/f/81631/1920x734/015e12654c/plastic-recycling-amsterdam-productieproces-van-afval-naar-plastic-recycling.jpg)

(Almost) infinitely recyclable

At the recycling plant in Amsterdam, they use Magnetic Density Separation (MDS): a special technology that makes the recycling of mixed plastic waste streams significantly more efficient.

Plastic waste is washed and finely ground into smaller particles, which separates the different plastic types from each other. The mix of different plastic types is then separated into up to four different plastic types using the MDS technique in one process step. These types have a purity of up to >99%. This end result is close in quality to new plastic and is therefore ideal for reuse in new products.

Effective communication

It is impressive to see such a huge production process in operation. However, especially during a visit to the factory, it can be difficult to get a good overview of all the steps. The machines are not arranged in a straight line like in the illustrations, and their size makes it difficult to see everything clearly. Therefore, we talk to the customer step-by-step to determine what each machine does and what is important to show, so that you can easily understand the whole process.

This way, everyone can be included in the story, from school children to investors.

From sketch to concept

We draw the entire process virtually or at the customer's table. This starts with simple line sketches to check if we have a shared image. When a visualization emerges, we can start the conversation and optimize together.

/f/81631/1200x660/cba97eae6d/productieproces-praatplaat-fabriek-customer-journey-procestekening-design-thinking-proces-employee-engagement-schets-tekening-productie.jpg)

After we have gone through everything together and discussed it, we start digital drawing. We work out all the details in this concept process drawing, which we then discuss with the client. By presenting all the details, they can experience how the information comes across. This way, we can gather feedback on how the message is received and where we can further optimize. Then we finalize the illustration, fine-tune any details with the customer, and deliver the digital illustration.

/f/81631/1200x697/cf10e9c3f3/plastic-recycling-amsterdam-concept-praatplaat-zakelijk-tekenen-productieproces-business-strategy-customer-journey-design-sprint-tekening-visueel-denken.jpg)

"Everyone uses the illustration!"

"There is no client who leaves the building without having seen the illustration" - Maikel van Dijk, Marketing & Communication Team Leader at Plastic Recycling Amsterdam

/f/81631/1920x734/7b9736e7d0/plastic-recycling-amsterdam-plastic-berg.jpg)

Ready for the future

An important consideration in the design and composition of the illustration is the desire to be able to make an animation in the future. Although the process is currently about 80-90% complete, it is constantly being optimized. When the next two factories are built, the process 2.0 can be adjusted in the illustration. Then we can create an animation so that the story can be told without a presenter. This way, we can inspire more people to recycle plastic infinitely.